What materials are dewatering screens suitable for? Dewatering screen is also called dewatering vibrating screen, tailing dry discharge screen, etc. It is a common type of vibrating screen for mining. From the power type, it can be divided into: vibrating dewatering screen (ordinary electric type) and multi frequency dewatering screen (vibrating motor type). These two dewatering screens are suitable for different materials. Let’s have a look.

First of all, vibrating screen type dewatering screen should be selected for materials with low moisture content and large particles. This type of dewatering screen is driven by ordinary motor through soft connection to drive the vibrator to make circular motion, and the exciting force is generally greater than that of the vibrating motor. The utility model can make the large particles jump out of the screen hole easily and avoid blockage. Generally, a six stage motor is used. Generally, the coal washing and stone washing industries use them in many ways.

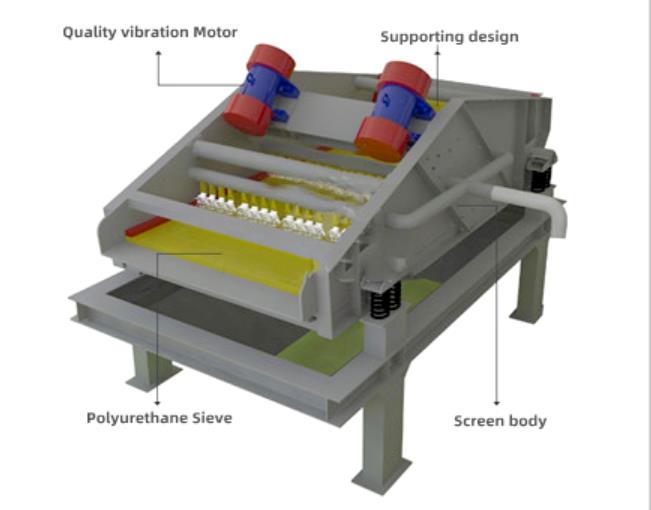

Secondly, for materials with large water content and small particles, vibrating motor type dewatering screen shall be selected, and four stage vibrating motor shall be used. Due to high frequency and fast speed, the material can run in a fast straight line to avoid adhesion, and there is no blockage due to small particles, a 4-level vibration motor should be used. In general, the chemical and pharmaceutical industries have more choices.

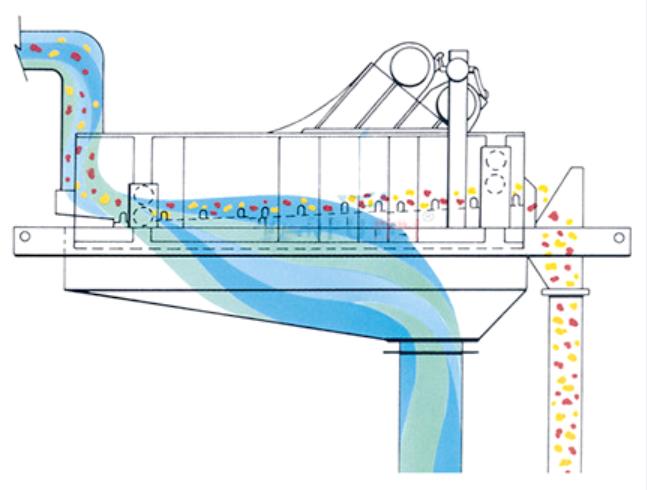

Third, high viscosity materials should use the built-in water shower device. The second flushing of the back half of the dehydration screen can reduce the adhesion of materials, improve the water washing function, and obtain good dehydration effect.

Fourth, in order to maximize the function of high-frequency dewatering screen, under normal circumstances, the side plate of the fourth level vibrating motor will break after installation, and many complex phenomena will occur. Because the angle and stress of the motor plate are difficult to control, causing various problems. Through repeated practice of special materials, the technical stability of mine vibrating screen has made great progress.

Materials with different characteristics are suitable for different types of dewatering screens, which is mainly to ensure that different materials can obtain good dewatering effect by using different dewatering methods, so as to meet the requirements of more different users for processing materials.