RZX series linear vibrating screen adopts high quality horizontal vibration motor as vibrating power source. While the material is thrown up on the screen, it can move forward in a straight line. The material passes through the multi-layer screen to produce several products and the unqualified over- and under-screen materials are discharged from their respective outlets to achieve the purpose of screening. RZX series linear vibrating screen can also be used for automatic operation in assembly line.

Linear Vibrating Screen Application

RZX series linear vibrating screen has a wide range of powder sieving and liquid filtration application cases in the screening and classification of granular and powdery materials in the chemical, food, metallurgy, mining, building materials, grain, abrasive, fertilizer, and coal industries.

Linear Vibrating Screen Features

◆ Adopt special grid structure design, which can quickly change the grid and tension quickly

◆ High screening efficiency and low noise

◆ The material travels on the screen surface is long, the screening fineness is high, and the processing capacity is large

◆ At the same time of screening, the material is conveyed over a long distance

◆ The screen surface spacing and inclination angle can be changed according to material particle size, penetration probability and productivity.

◆ Different shapes and structures can be designed according to the production site.

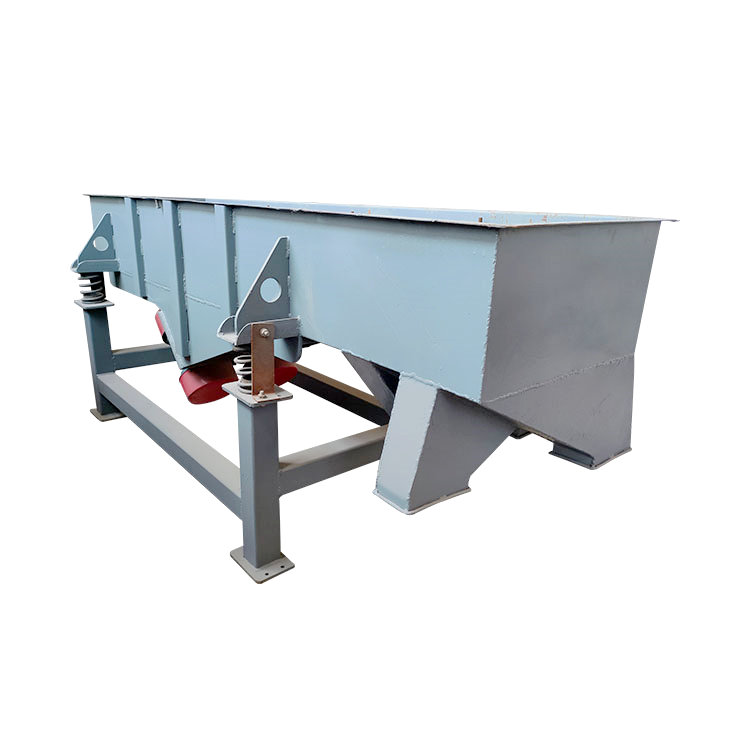

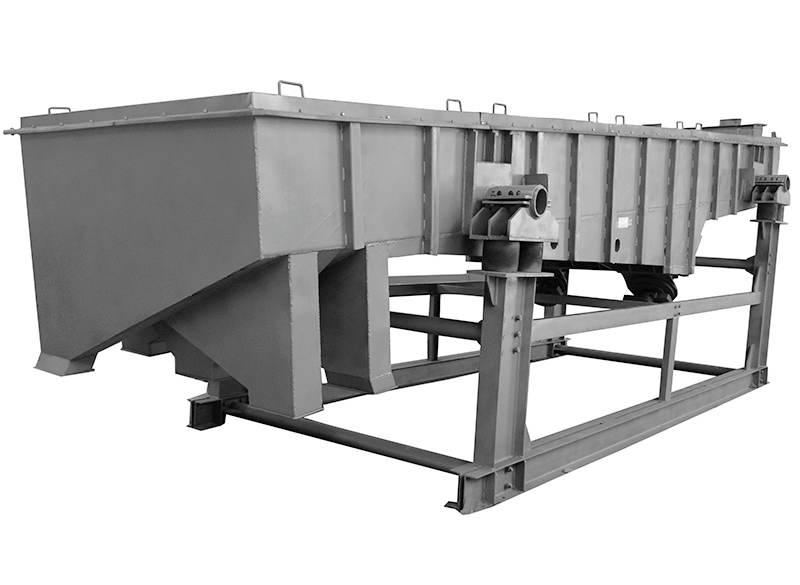

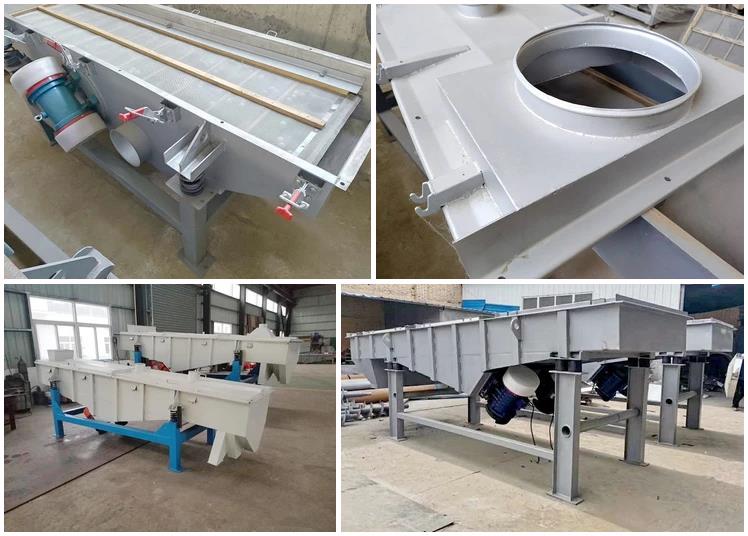

Linear Vibrating Screen Machine factory details

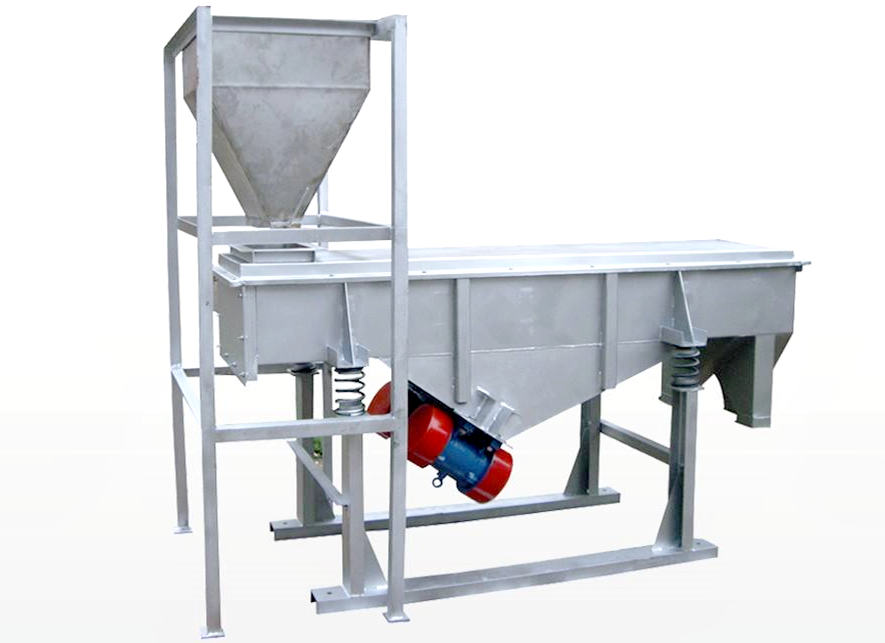

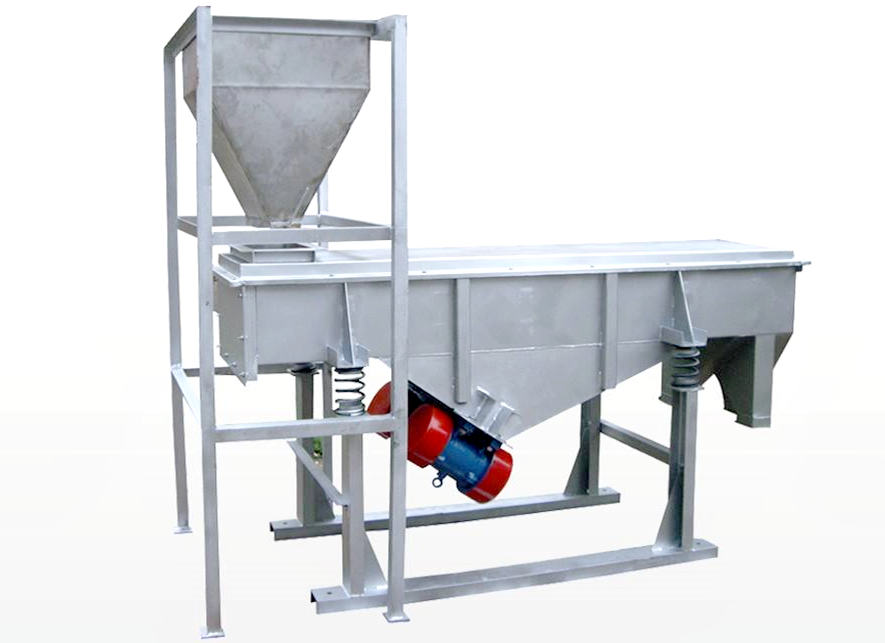

Linear Vibrating Screen working Principle

RZX series linear vibrating screen is composed of vibration motor, screen box, screen mesh, vibration transmission body and vibration damping device. When the two horizontal vibration motors installed longitudinally on the screen body rotate relative to each other. The eccentric blocks at both ends of the two vibration motors generate the rated excitation force, the excitation forces generated in the lateral direction cancel each other, and the excitation force in the longitudinal direction is transmitted to the overall screen surface through the vibration transmission body, so that the materials on the screen surface Affected by its exciting force, it jumps on the screen surface to the direction of the discharge port. The materials smaller than the sieve holes fall to the lower layer through the sieve holes, and the materials larger than the sieve holes will be intercepted and put on the net. After that, the materials will flow out through the discharge port after continuous jumping to complete the classification of the materials. Linear vibrating screen machine is the most widely and commercial apply industrial vibro sieving machines than the normal round type rotary vibrating sieve machines.

Linear Vibrating Screen Technique data:

| Model | Screen Size(mm) | Material size(mm) | Inclined Angle(°) | Amplitude(mm) | Layer(s) | Power(kw) |

| RZX520 | 500×2000 | 0.074~50 | 0°~7° | 4~8 | 1~5 | 2×(0.4~0.75) |

| RZX525 | 500×2500 | 2×(0.4~0.75) | ||||

| RZX530 | 500×3000 | 2×(0.75~1.1) | ||||

| RZX1030 | 1000×3000 | 2×(1.5~1.8) | ||||

| RZX1035 | 1000×3500 | 2×(1.5~2.2) | ||||

| RZX1225 | 1200×2500 | 2×(1.5~2.2) | ||||

| RZX1230 | 1200×3000 | 2×(1.8~3) | ||||

| RZX1235 | 1200×3500 | 2×(1.8~3) | ||||

| RZX1530 | 1500×3000 | 2×(2.2~3) | ||||

| RZX1540 | 1500×4000 | 2×(2.2~4) |