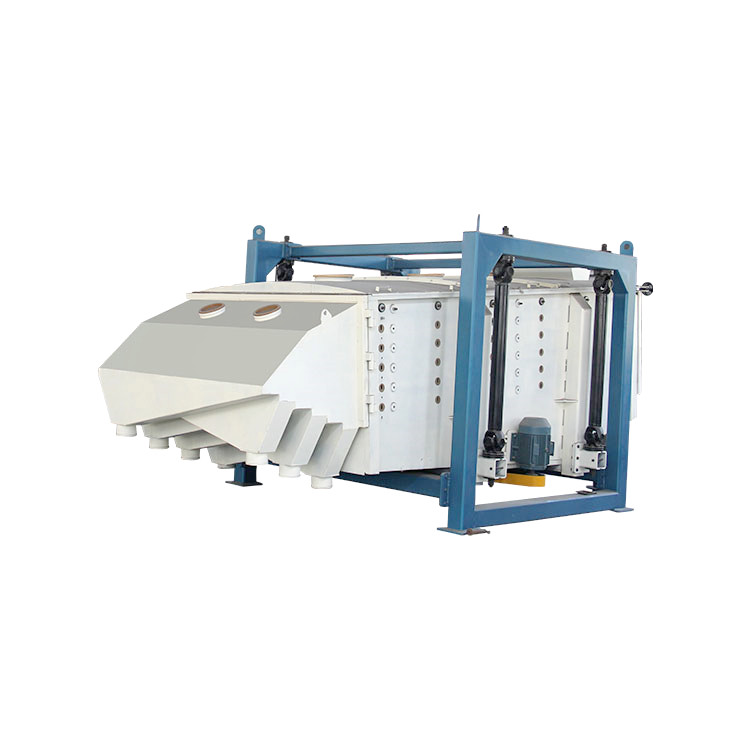

High efficient rectangular gyratory sifter machine is a heavy duty screening equipment with high precision and large output capacity. It has good self-cleaning effect, high screening utilization rate, durable long working life and good sealing effect.

Gyratory Sifter Machine Working principle

The basic working principle of the rectangular gyratory sifter machine is : Judging from the movement trajectory of the screen box, which is the shaking body of the screen machine, the square gyratory screen is also called a reciprocating screen. The vibration force generated by the driving device is an inertial force that changes in a certain direction around a fixed axis. Its essence is caused by eccentricity. The reciprocating inertial force formed by the rotation of the wheel around the fixed axis. According to the structural characteristics and working principle of the swing screen, the screen surface is generally arranged horizontally or slightly inclined (the inclination angle is 0°~5°). The working principle of the gyratory screen is that after the screen machine is started, the shaker of the screen machine, that is, the screen box reciprocates back and forth under the action of inertial force, and the screen box drives the screen surface to periodically shake, so that the materials on the screen surface follow the screen box. It is a plane rotary motion together, during which, the material smaller than the sieve surface aperture falls to the lower layer through the sieve hole and becomes the under-sieve material, and the material larger than the sieve surface aperture is discharged from the discharge port after continuous tumbling and jumping motion to complete the screening work.

Gyratory Sifter Machine Features and Advantages

Large screening volume, multi-layer grading design, one machine is divided into two groups, one machine is used for multiple machines, and the output is doubled.

Fully enclosed structure, no dust flying, small vibration and low noise of the screen machine, which meet the requirements of environmental protection.

Flexible screening, the acceleration is 4-5 times lower than that of ordinary vibrating screens, and the service life is increased, thereby reducing maintenance costs.

It is more convenient to change the net, the operation is simple, and it is firm and reliable.

Large-scale electrostatic spraying process, the equipment is more beautiful, wear-resistant and rust-proof

Gyratory Sifter Machine Application

The gyratory sifter machine is widely used in chemical and new materials, metallurgy, metal powder, mineral powder, food, salt, sugar, abrasive, feed and other industries. The gyratory motion generated by the exciter is transmitted to the screen surface through the square gyratory screen, so that the material can be quickly dispersed in the front of the screen machine, so as to achieve the purpose of screening.