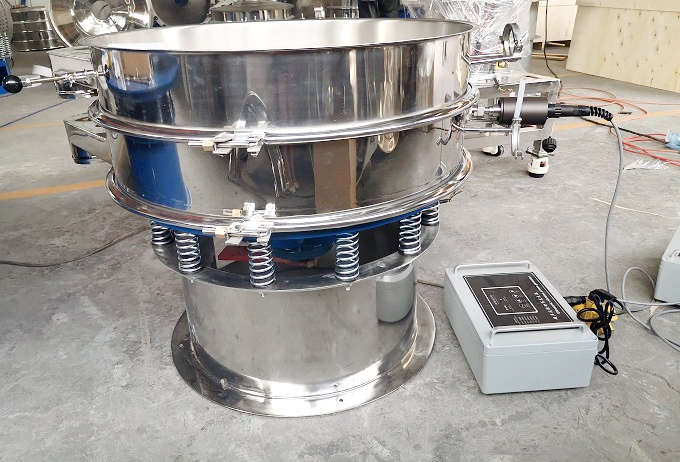

Ultrasonic vibrating screen machine is our new fine powder sieving machine equip with our patent ultrasonic clearing system. Based on years of experience in fine grading, REEGER has developed a “high precision, high stability” RC high-precision vibrating screen separator through technical cooperation with Germany. RC type intelligent vibration ultrasonic controller changes the incompatibility and non-adjustability of a single frequency, truly realizes the organic combination of ultrasonic wave and vibrating screen, and its performance reaches the level of international similar products and completely surpasses it. Solve the screening problems such as strong adsorption, easy agglomeration, high static electricity, high precision, high density, light specific gravity, etc., with superior performance! A big breakthrough was achieved in the performance of ultrasonic vibrating screen. The screening accuracy can be increased by 1-100%, and the output can be increased by 1-20 times; it can truly meet the needs of industrial production above 500 mesh!

Ultrasonic Vibrating Screen Machine Factory

Ultrasonic vibrating screen machine Working principle

We convert 220V, 50Hz or 110V, 60Hz electric energy into 18KHz high-frequency electric energy, input the ultrasonic cleaning transducer through the ultrasonic power supply, and turn it into 18KHz mechanical vibration, so that the ultra-fine powder can receive huge ultrasonic acceleration, thereby inhibiting the Adhesion, friction, leveling, wedging and other blocking factors to improve screening efficiency and net cleaning efficiency. To achieve the purpose of high-efficiency screening and net cleaning, making the screening of ultra-fine powder an easy task. Especially suitable for users of high value-added fine powder.

Round Vibrating Sieve Machine Techanical Parameters

| Model | Diameter(mm) | Efficient dia(m2) | Layer | Mesh size | Power(kw) | Size(mm) |

| R-400 | D400 | D380 | 1-5 Layers | 3-500 | 0.25 | 580*580*560 |

| R-600 | D600 | D600 | 1-5 Layers | 3-500 | 0.55 | 800*800*750 |

| R-800 | D800 | D750 | 1-5 Layers | 3-500 | 0.75 | 900*900*750 |

| R-1000 | D1000 | D900 | 1-5 Layers | 3-500 | 1.1 | 1160*1160*810 |

| R-1200 | D1200 | D1100 | 1-3 Layers | 3-500 | 1.5 | 1360*1360*980 |

| R-1500 | D1500 | D1450 | 1-3 Layers | 3-500 | 2.2 | 1850*1850*1130 |

| R-1800 | D1800 | D1750 | 1-3 Layers | 3-500 | 3 | 2200*2200*1050 |

| R-2000 | D2000 | D1950 | 1-3 Layers | 3-500 | 4 | 2350*2150*1125 |

| Remark: | 1. 1-5 layers Available. 2. Stainless Steel 304 Materials. 3. Bouncing balls or Ultrasonic Cleaning. 4. Custom Services. | |||||

Ultrasonic vibrating screen machine factory detail

Ultrasonic vibrating sieve machine Features

◆ Decompose the adhering substances and reduce the on-screen material, generally 5-20 times more than the vibrating screen machine without ultrasonic installation;

◆ It truly solves the screening problems of materials with strong adsorption, easy clumping, high static electricity, high precision, high density and light specific gravity;

◆ Reduce or exempt network cleaning time;

◆ No contamination of powder by auxiliary objects such as bouncing balls;

◆ Maintain the mesh size and stabilize the screening accuracy;

◆ Reduce the number of repeated sieving;

Ultrasonic vibrating screen machine for powder application

Reeger Machinery is a solution provider that stay focused on fine material screening, impurity removal and dust-free conveying. If you have the purchasing needs or questions when using the vibrating sieve machines, Just email and Contact us Now! you will get our engineer suggestion and answers quickly! CONTACT US!