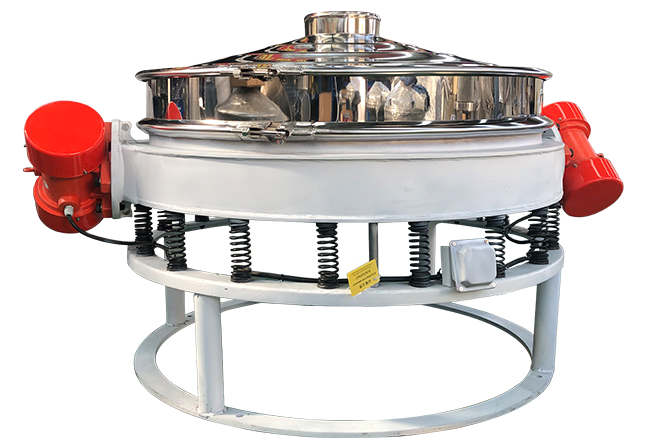

Direction discharging high frequency vibrating screen is widely used for the food powder sieving to remove the impurity. Especially for wheat flour powder sieving functions. It has large loading capacity, high frequency and high sieving efficiency advantages. The two vibrating motors installed on two sides of the vibrating screener machine. It generally is single layer vibrating screen and often use together with other equipment such free dust feeding station.

High Frequency Vibrating Screen Machine Different Types

Flour Sieving High Frequency Vibrating Sieve Machine for Malaysia Clients

One of our Malaysia client would like a vibro sieving machine to sieve lump flour from the large quantity powder and remove the iron. They demand 3t per hours. The sieve mesh is 80 mesh. According to client demand, we recommend the dia 800 direction discharging vibrating screen with full stainless steel material and install the magnet at the outlet of the vibrating screener machine. Meanwhile the client also mentioned they pour the powder directly from the bag , the powder is very dusty, so we recommend the client increase free dust feeding station. The client is interested in the machine because it can solve their environment protection issue and worker health safe issue. Therefor, we provide the solution as follows:

Malaysia Flour Sieving High Frequency Vibrating Sieve Main Parameters

Machine model: RZP800 vibrating screen machine

Dia: 800mm

Sieve mesh: 0.25-20mm

Motor power:2*0.25

Free dust feeding station size: 1000*1000mm

Machine material: Full stainless

High frequency vibrating screen machine equip with the dust free feeding station and vacuum feeder conveyors application show.

Circular Vibrating Sieve Machine Techanical Parameters

| Model | Diameter(mm) | Efficient dia(m2) | Layer | Mesh size | Power(kw) | Size(mm) |

| R-400 | D400 | D380 | 1-5 Layers | 3-500 | 0.25 | 580*580*560 |

| R-600 | D600 | D600 | 1-5 Layers | 3-500 | 0.55 | 800*800*750 |

| R-800 | D800 | D750 | 1-5 Layers | 3-500 | 0.75 | 900*900*750 |

| R-1000 | D1000 | D900 | 1-5 Layers | 3-500 | 1.1 | 1160*1160*810 |

| R-1200 | D1200 | D1100 | 1-3 Layers | 3-500 | 1.5 | 1360*1360*980 |

| R-1500 | D1500 | D1450 | 1-3 Layers | 3-500 | 2.2 | 1850*1850*1130 |

| R-1800 | D1800 | D1750 | 1-3 Layers | 3-500 | 3 | 2200*2200*1050 |

| R-2000 | D2000 | D1950 | 1-3 Layers | 3-500 | 4 | 2350*2150*1125 |

| Remark: | 1. 1-5 layers Available. 2. Stainless Steel 304 Materials. 3. Bouncing balls or Ultrasonic Cleaning. 4. Custom Services. | |||||

The free dust powder feeding station can absorb the dust when the feeding by bag and avoid the dust spillage. Along the environment protection demand increase, many factories are introducing the matching equipment to reduce the factory environment pollution. Along these machines, vacuum feeder conveyor also a matching environment protection equipment which is full closing conveying and no dust spread during while conveying course.

Reeger machinery not only can provide single sieving or conveying product, but also can provide integral solution of production line. If you are interested, welcome to contact us for more details.