Using Circular Vibrating Sieve Machine to Test Screening of Small Amounts of Materials for Optimal Results is really important and necessary. by doing this can greatly maximum the material screening effect and getting more economic benefits. The following are the Circular Vibrating Sieve Machine factory Debugging and Right Operating Process. hope useful for you.

Powder Sieving Circular Vibrating Sieve Machine Factory Debugging Process

When it comes to screening small amounts of materials, a vibrating sieve machine is an ideal piece of vibro sieving machine to use. It is designed to efficiently and accurately screen materials by using vibrations to move them through a series of screens with varying mesh sizes. However, to achieve the best results with a vibrating sifter machine, it’s important to adjust the angle and weight of the eccentric blocks on the vibration motor based on the specific screening needs of the material being processed.

Selecting Right Circular Vibrating Sieve Machine

1. The first step in using a vibro sifter machine is to select the appropriate mesh size for the material being screened. This will help to ensure that the material is effectively screened and that larger particles are removed from the final product. Once the mesh size has been determined, the angle and weight of the eccentric blocks on the vibration motor can be adjusted to optimize the screening process.

Adjusting the angle of the vibrating sieve machine eccentric blocks

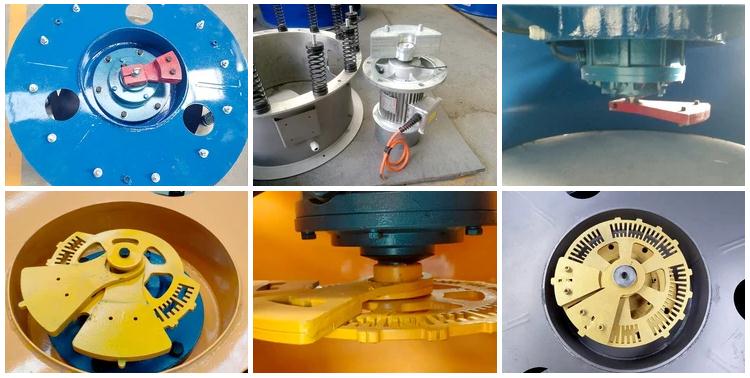

2. To adjust the angle of the eccentric blocks, the Vibrating sieve machine should be turned off and the blocks should be loosened using a wrench. The angle can then be adjusted by moving the blocks up or down on the motor shaft. Once the desired angle has been achieved, the blocks should be tightened using a wrench to secure them in place.

Adjusting the weight of the vibrating sieve machine eccentric blocks

3. To adjust the weight of the eccentric blocks, small weights can be added or removed from the blocks. This will change the balance of the motor and can help to improve the quality of the screening process. To add or remove weights, the blocks should be loosened using a wrench and the weights should be added or removed as needed. Once the desired eccentric blocks weight has been achieved, the blocks should be tightened using a wrench to secure them in place.

Once the adjustments have been made, the circular vibrating sieve machine can be started and the material can be fed uniform through the machine. The vibration motor will then move the material through the screens, separating it according to the desired mesh size. By adjusting the angle and weight of the eccentric blocks, the screening process can be optimized to achieve the best possible results.

In conclusion, when using a vibrating sieve machine for industrial powder sieving and grading functions, it’s important to adjust the angle and weight of the eccentric blocks on the vibration motor to optimize the screening process. By taking the time to make these adjustments, it’s possible to achieve the best possible results and ensure that the final product meets the desired specifications. Welcome to contact us for more info about the vibrating sieve machine!