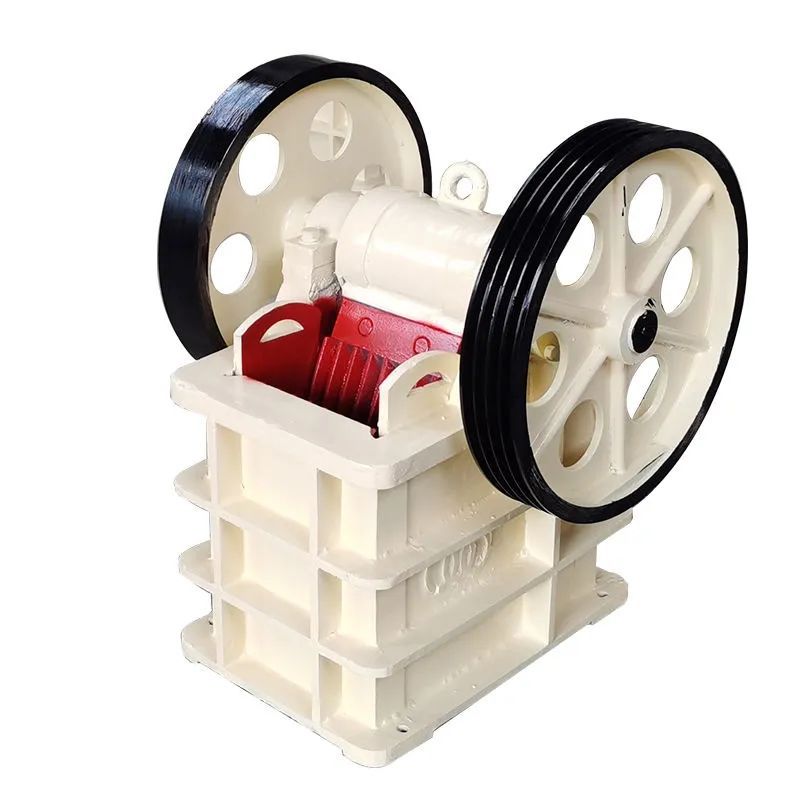

The high efficient industrial stone grinding small type mini jaw crusher machine is a samll and flexible crushing machine for many materials primary coarse crushing functions with advantages of High ratio of crushing, Homogeneous final grain size, Simple structure, Reliable working condition, Easy maintenance and Low operating cost. etc

This type of Mini sand Jaw Crusher machine main components are: fixed jaw plate, activities, jaw, rack, upper and lower guard, adjust the seat, moving rods and other components.

Sand Crushing Jaw Crusher Machine Selecting

How to choose the suitable and right sand crusher machines for your sand crushing so as to achieve large capacity, high crushing efficiency and low commercial cost? the following are some basic tips we need to consider, if you want to learn more about the cursher machine and some other sand processing equipments, welcome email us.

1.What is the raw material for crushing and tell us you your sand processing lines such as the screw feeding conveyor, linear vibration screen, fine powder vibrating sceen machine. etc

2.What is the crushing capacity per hour you required? how long working hours per day?

3. What is the maximum input size of the raw material?

4. What is the output size and application for the final products?

5. How to fix the crusher machine, on the concrete floor or above the stand.

Small type jaw crusher machine Applications

This small type of mini sand crusher machine have many advantages, such as big crushing ratio, equal product granularity, simple structure, reliable working condition, convenient repair and economical operation, they are widely used in the works of mine, smelting, building material, road, railway, irrigation, chemical industry etc. Mainly apply for Mining crusher crushing materials including granite, basalt, limestone, river stone, sandstone, shale, iron ore, copper ore, building construction, construction wastes etc.