Double Ribbon Blender Mixer Machine is widely applied for powder mixing in chemical, biological, and construction material. The ribbon blender mixer can mix powder, granule, and fiber especially in battery, construction, environmental, mineral and agricultural line.

Ribbon Blender Mixer Machine Structure show

The equipment consists of a container, a spiral stirring blade and a transmission part: the spiral blade is generally made into two layers or three layers, the outer helix collects the material from both sides, and the inner helix conveys the material from both sides to form convection mixing.

Ribbon Blender Mixer Machine Features

Large loading factor and small equipment footprint

Low calorific value, high stirring efficiency, and uniform mixing

The mixing is uniform and loose, there are very few dead ends, the material is convenient to discharge, and it is easy to clean

Equipment is not easy to wear

Ribbon Blender Mixer Machine Suitable mixing materials

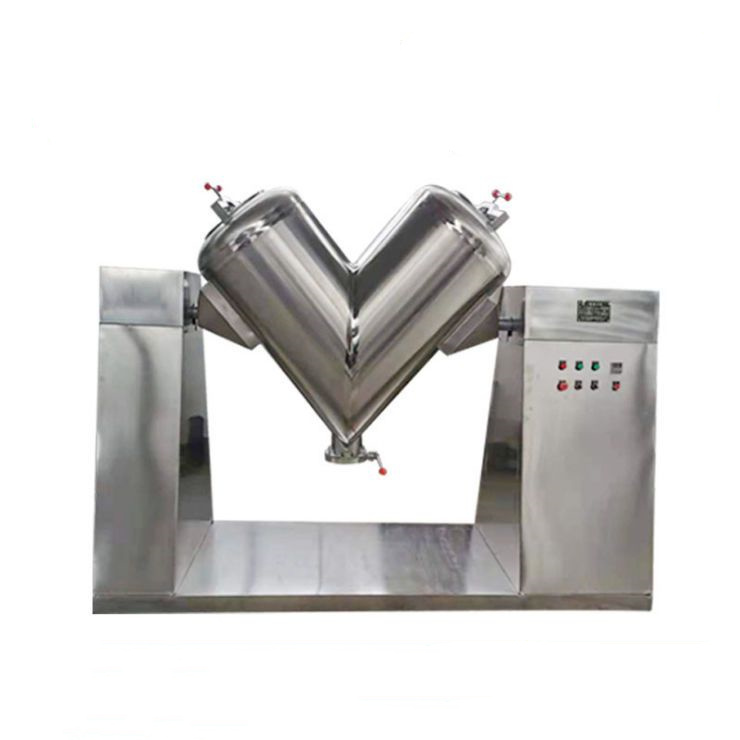

Ribbon mixers are generally used for the mixing of viscous or cohesive powders and granules, as well as the mixing of liquid and paste materials added to the powders and granules. It is widely used in chemical industry, battery raw materials, coatings, dyes, pesticides, pharmaceuticals, food, feed, additives, refractory materials, new materials, electronic plastics, ceramics, fertilizers, metallurgy, mining, dry powder mortar, special building materials and other industries. Mixing of solids and solids, powders and liquids. The mixing efficiency of the horizontal twin-ribbon mixer is twice that of the conical mixer.

Ribbon Blender Mixer Machine technical parameter

| Specification | HMR-100 | HMR-300 | HMR-500 | HMR-1000 | HMR-1500 | HMR-2000 | HMR-3000 | HMR-5000 |

| Wrking capacity(m³) | 0.28 | 0.48 | 0.7 | 1.5 | 2.1 | 3.2 | 4.3 | 6.4 |

| Working capacity(kg) | 100 | 300 | 500 | 1000 | 1500 | 2000 | 3000 | 5000 |

| Speed (r/min) | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 |

| Power(kw) | 3 | 4 | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 |

| Weight(Kg) | 480 | 780 | 1180 | 1680 | 1980 | 2280 | 2560 | 2890 |

| L(cm) | 180 | 240 | 270 | 310 | 310 | 350 | 375 | 390 |

| W(cm) | 70 | 80 | 90 | 110 | 110 | 130 | 135 | 164 |

| H(cm) | 150 | 190 | 200 | 200 | 200 | 240 | 240 | 270 |

| Exit off the grand(cm) | 60 | 60 | 80 | 80 | 80 | 100 | 90 | 100 |