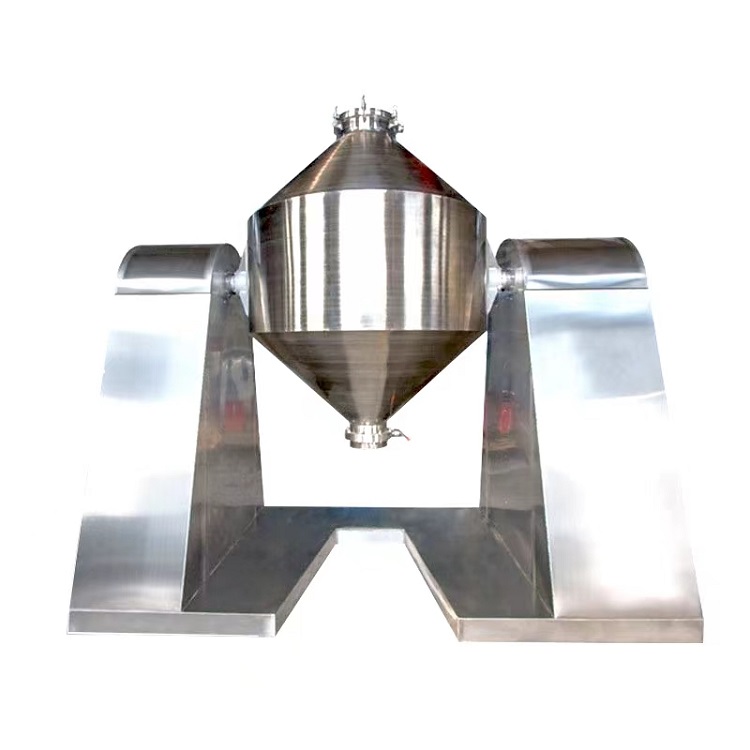

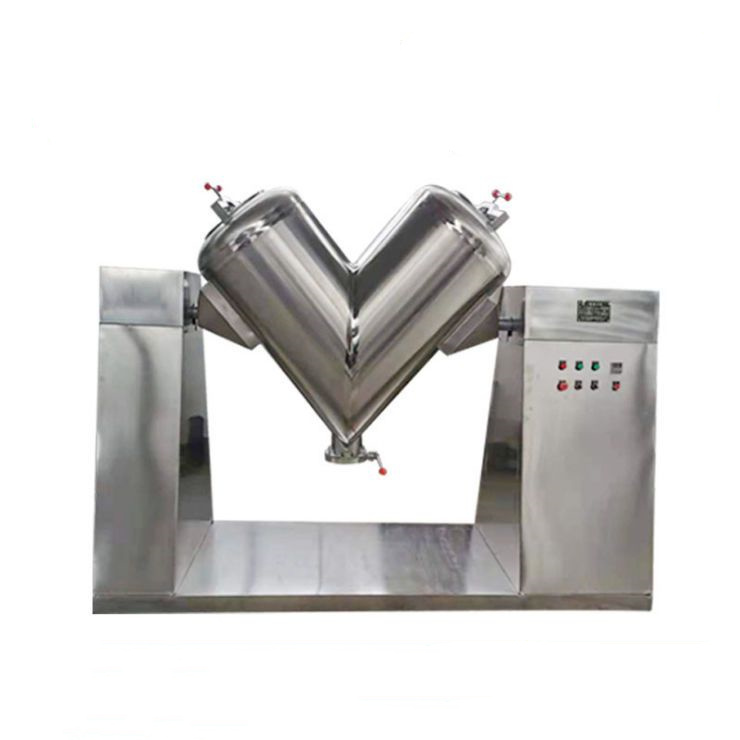

The 3 D mixer machine is a kind of full closed powder mixer machine with advantages of high mixing efficient, energy saving, large loading capacity, short mixing time without germ and dust. When the material is being mixed, no centrifugal force effect or situation of gravity segregation or laminar accumulation occurs.

The mixing barrel of the 3D mixer machine moves in multi-direction movement. For the materials, there is no centrifugal function, without the specific gravity segregation and the layer division. For each of build-up phenomenon, there is the remarkable weight rate. The material charge rate of barrel is big. Maximum rate can be up to 90%(the normal mixer has only 40% charge rate.). It is high in efficiency and short in the mixing time. The barrel adopts arc shape connections and its well polished. The machine id the desired product in various industrial powder mixing functions at present.

The Three Dimensional Mixer machine barrel for charging the materials is driven by the driving shaft. The barrel body carries on the repeated level movement, rotation, turning and other complex movements so that the materials will carry out the three dimensions and complex movements along the barrel body so as to realize the various movements of the materials. through disseminating, gathering, agglomerating and mixing to realize uniform mixing.

This type of 3D mixer machine is used for mixing the powder state and grain state materials with the high uniformity in the pharmaceutical, chemical, food, light-industry, electronic, mechanical, metallurgical, nation defense industries and other science and technology institutes.