why by applying the vibrating sifter machine can greatly increase the Coconut Shell Activated Carbon sieving efficiency and accuracy? We all know the vibrating sieve machine is designed to efficiently and accurately separate particles of different sizes. When used to sieve Coconut Shell Activated Carbon, it can greatly increase the sieving efficiency and accuracy for the following reasons.

Coconut Shell Activated Carbon Powder Sieving Vibrating Sifter Machine Advantages

High-frequency vibration: The vibrating sifter machine uses high-frequency vibration force from the strong design vibrating motors to move the Coconut Shell Activated Carbon particles on the sieve surface, which helps to separate particles of different sizes more quickly and efficiently.

Multiple layers of screening: The vibrating sieve machine usually has multiple layers of screening(from 1 to 5 Layers), allowing for the separation of particles into different size fractions simultaneously.

Precise mesh size: The sieve mesh of the vibrating sieve machine can be precisely adjusted to match the particle size distribution of the Coconut Shell Activated Carbon, ensuring that all particles within the desired size range are effectively separated.

Simple Mechanical Structures Design: Simple Mechanical Structures Design for easy operating and low maintenance cost. by the bouncing balls and rings solving the screen mesh blocking problems. Few minutes for changing the screen mesh and easy and quick cleaning features.

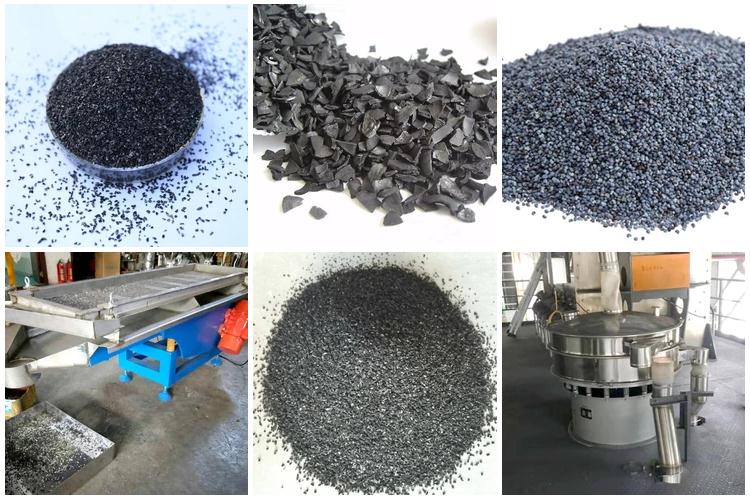

Coconut shell activated carbon is a kind of black irregular granular carbon particles. Coconut shell activated carbon is made of coconut shells from Vietnam, Indonesia, and other countries as raw materials. After refined and processed and selected with a vibrating sieve machine getting the quality specifications of different sizes of the Coconut shell activated carbon.

Coconut Shell Activated Carbon Sieving Vibrating Sifter Machine Applications

The mesh size of coconut shell activated carbon is different, Each type of activated carbon has a standard mesh number for adsorption properties. Coconut shell activated carbon manufacturers can express the mesh number as 6-10 mesh, 10-20 mesh, 24-48 mesh and so on. Just choose the different mesh sizes of the screen deck equip with the vibro sieving machine can achieve the final sieving coconut shell activated carbon powder sizes.

Powder Sieving Vibrating Sifter Machine Equip with Feeding Conveyor Equipments

Reeger Machinery can also equip the coconut shell activated carbon sieving machine with different types of feeding conveyor equipments like vacuum feeding conveyor, screw conveyor, Z type bucket elevators etc. greatly increase the materials processing efficiency and have an eco-friendly and healthy working environment. Welcome Contact Us for more info!