How Airflow Sifter Machine separating the recycled rubber powder? Waste tire rubber powder came frome the crushed waste tires, especially all steel radial tires, into fine rubber powder of 40-120 meshes under normal temperature.The raw and coarse rubber powders will be separating by the rotary vibrating sieve machine, milling processing, fine powder sieving airflow sifter machine, and then get the need products.

Due to the high viscosity of rubber powder, if the ordinary vibrating screen is used to complete the screening process in the rubber powder production process, the effect is not good and the screening efficiency is very low. However, the use of air flow rotary sieve machine can achieve better results.

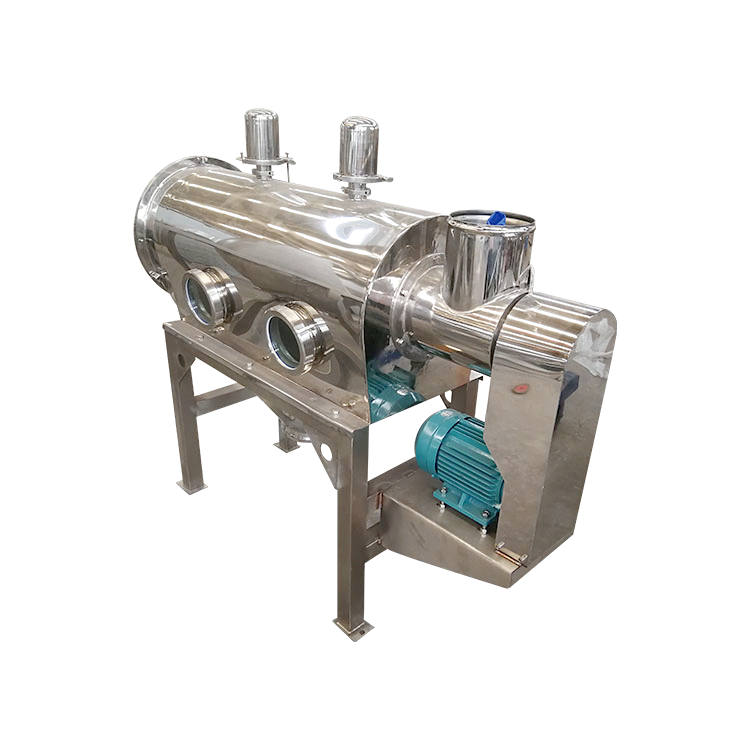

Airflow sifter machine is a high-precision screening equipment for fine powder screening, which is widely used in chemical industry, medicine, food, paper making, metallurgy, building materials, rubber powders, machinery and other industries. The rotary sieve sifter can be used for continuous screening of powdery materials with a fineness range of 80-500 meshes, and the screen can be replaced at will. The air flow rotary sieve (air flow sifter) has high screening efficiency, large output, accurate fineness, no oversize mixing phenomenon, no load on the vertical installation of the screen, long service life, wide range of fineness, totally enclosed structure, no dust spillage, low noise and energy consumption, continuous operation and convenient maintenance.

fine and ultra-fine powder sieving air flow sifter machine application show

fine and ultra-fine powder sieving air flow sifter machine application show