Plate and Frame Automatic Filter Press Machine is an important pressure filtration device for solid-liquid separation with advantages of large capacity, easy operating, simple structure, good filtering effect, and reliable performance. we will introduce the filtering operation steps of the plate and frame filter press machine, including the precautions and operating norms for each step.

Plate and Frame Automatic Filter Pressure Machine Filtering Operation Steps

Before applying the automatic pressure filter machine, carefully read the instructions, check each components of the filter press equipment, and ensure that it is clean and well-maintained. Then install the filter cloth, align the filter press, and adjust the tightness of the compression bolts to ensure that it is reliable and tight.

Feeding and filtering: Place and pumping in the materials to be filtered to automatic filter press machine, then close the plates, and connect the squeeze plate pump to the feeding pipe. Start the machine and feed the slurry evenly into the filter press. During the feeding process, pay attention to the volume, concentration, and flow rate of the slurry to ensure that the filter press operates within its capacity. Compression and filtration: When the material is filled, close the feed valve and begin the compression process with the compression pump. Gradually increase the pressure until the filter cake is formed. At this time, stop the feeding and discharging process, and maintain the pressure for a certain time according to the solid-liquid separation requirements. Discharging: Open the discharge valve and discharge the filtrate. After the pressure is released, lift the push plate by qualified personnel, and remove the filter cake using a scraper. During the operation, avoid any violent actions that may damage the filter cloth or affect the filter press’s performance. Cleaning and maintenance: After the filtration process is complete, turn off the pressure filter machine, wait for the pressure to be fully released, and then dismantle the filter cloth for cleaning. Check the equipment and each component for any defects or problems, and maintain them regularly to ensure the smooth operation of the equipment.

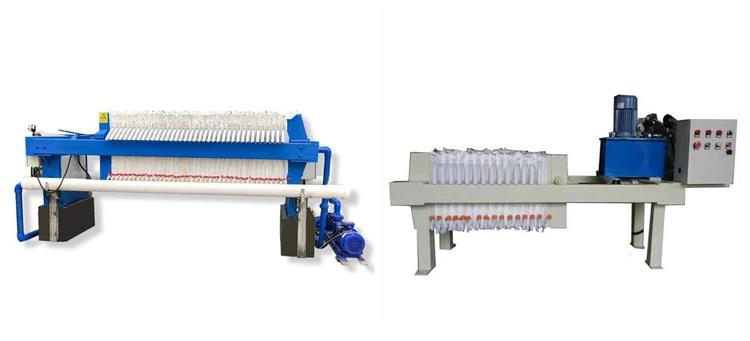

Plate and Frame Automatic Filter Pressure Machine Factory

The right and suitable operation steps of the plate and frame filter press are relatively simple, but it requires strict adherence to the operating norms and precautions of each step to ensure that the machine operates smoothly and has a good filtering effect. Operators should be properly trained and familiar with the safe operation procedures to avoid any accidents. and also for the long working time of the machine. Reeger Machinery can supply the most suitable and factory low prices solid liquid separators for you. Welcome to Contact Us for more info!