How to Order a High Mixing Efficiency Ribbon Blender Mixer Machine? When it comes to selecting a ribbon mixer machine, it is important to focus on the key aspects that are crucial to achieving high mixing efficiency. These factors include the blending principle, design, performance, and efficiency. Here are some tips to help you choose the suitable and right ribbon blender mixer for your mixing operations.

Order a High Mixing Efficiency Ribbon Blender Mixer Machine

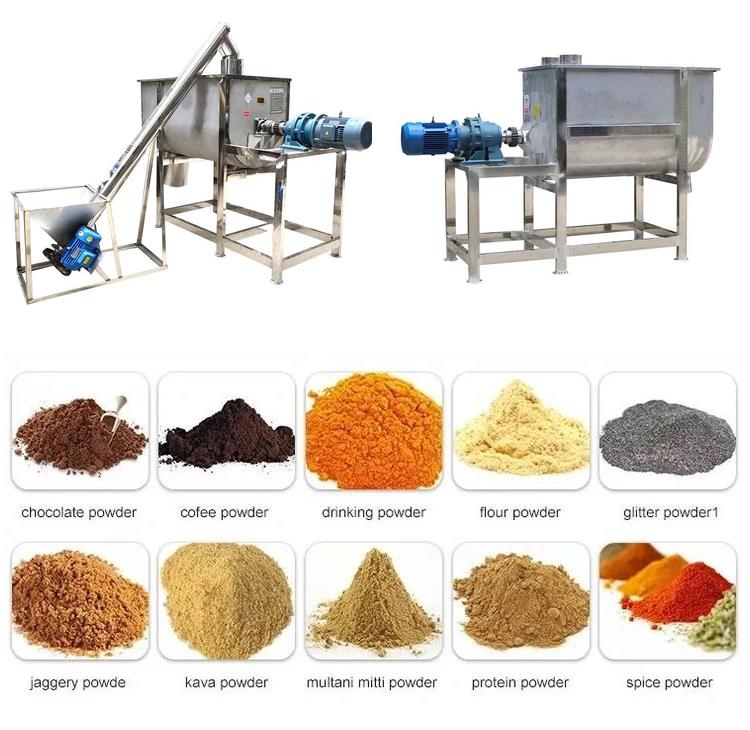

There are various sizes, designs, and configurations of ribbon mixer machines available in the market. You need to consider factors such as the feeders, the discharge mechanism, dust control, and cleaning. Ensure that the design and capacity of the blender sufficiently meet your production requirements and minimize downtime.

Considering the Mixing Powder Features and Consider the Blending Principle. Ribbon Mixers consist of two blending shafts with helical ribbons rotating in opposite directions. They work on the principle of convective mixing, in which the material is moved from one end of the blender to the other end. Make sure the mixing principle meets your specific product requirements. To evaluate the performance of the ribbon blender, Look for blenders that offer high rates of mixing efficiency and reduce processing time. The energy efficiency of ribbon blenders can significantly impact the manufacturing cost. Look for blenders that are designed to consume less power without compromising the quality of the mixing. You should always prioritize safety and maintenance when selecting a ribbon blender. Look for a ribbon blender that is easy to clean, inspect, and maintain. A well-maintained blender reduces downtime and increases operational efficiency. It should also comply with safety regulations and standards to ensure safe operation.

Eelecting the right ribbon blender mixers depends on the specific requirements of your product and operation. By focusing on these key factors, you can make an informed decision and select the most suitable ribbon blender that provides consistent and high-quality blends while keeping operational costs low.